5 Advantages of Servo Drive Preventative Maintenance

Is it sensible to pay for servo drive preventative maintenance on an old unit that seems to be working perfectly fine? Wouldn’t it better to simply let it run until it fails…and then have it repaired?

For those facing the same dilemma with their older model servo drives, we’ve compiled a list of reasons why Preventative Maintenance probably makes the most sense.

1. Everything Breaks…It’s Just a Matter of Time

Electronic and mechanical components are designed to achieve a certain amount of work hours over their lifespan. However, some parts naturally break down faster than others. Our experience has found that a drive’s components are particularly susceptible to aging. Unfortunately, some components may be critical to a whole circuit; their failure, therefore, can cause damage to other portions of the drive. To prevent this type of costly repair, it is wise to replace certain components from time to time.

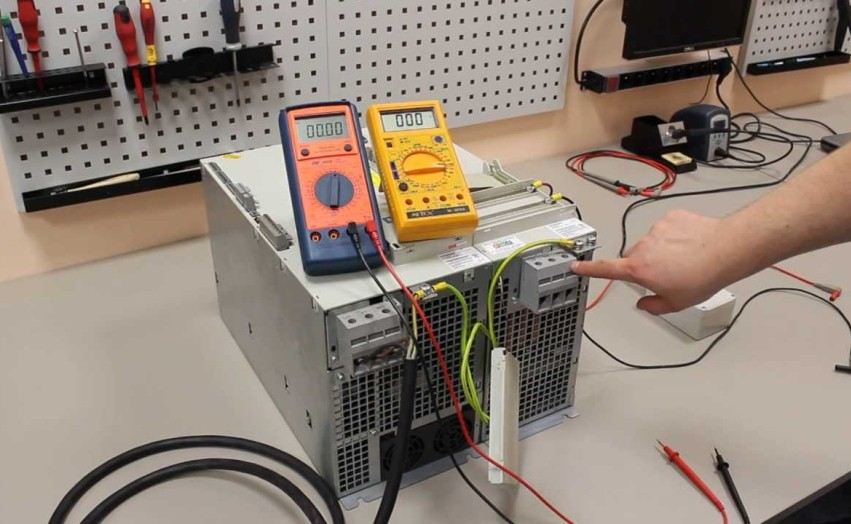

2. Around 80% of Repairs Can Be Avoided by Timely Maintenance

Our repair data consistently reveals that specific components are the reoccurring culprits behind most servo drive failures. We’ve become so certain of this that we automatically replace those trouble-prone components before even beginning our troubleshooting process.

3. Preventative Maintenance Saves You Money Two Ways

Servo drive repairs usually require a lot more bench time than Preventative Maintenance service. While this is directly reflected in the relatively higher expense of the repair, one shouldn’t overlook the cost that a malfunctioning servo drive also inflicts on productivity. Failures always seem to occur at the most inopportune and critical times. Preventative Maintenance, on the other hand, can be handled when convenient to a company’s production schedule.

4. Catch Ailing Electrolytic Capacitors While You Can

The servo drive components that cause the most issues are aging electrolytic capacitors. Unfortunately, they often leak electrolyte on the circuit board, causing physical damage to traces and other components. It is always preferable to replace them at certain age before they reach this destructive stage.

5. Follow the 1 Year Rule of Thumb

Experience has proven that it is best to have servo drive preventative maintenance conducted on your equipment every 1 years. For drives operating in dirty and hot environments, we suggest even more frequent preventative care. Drives of that sort often arrive at our repair center after having been heavily contaminated with oil and other chemicals. It is critical to clean these contaminants from the circuit boards before they cause tracks corrosion and components damage.